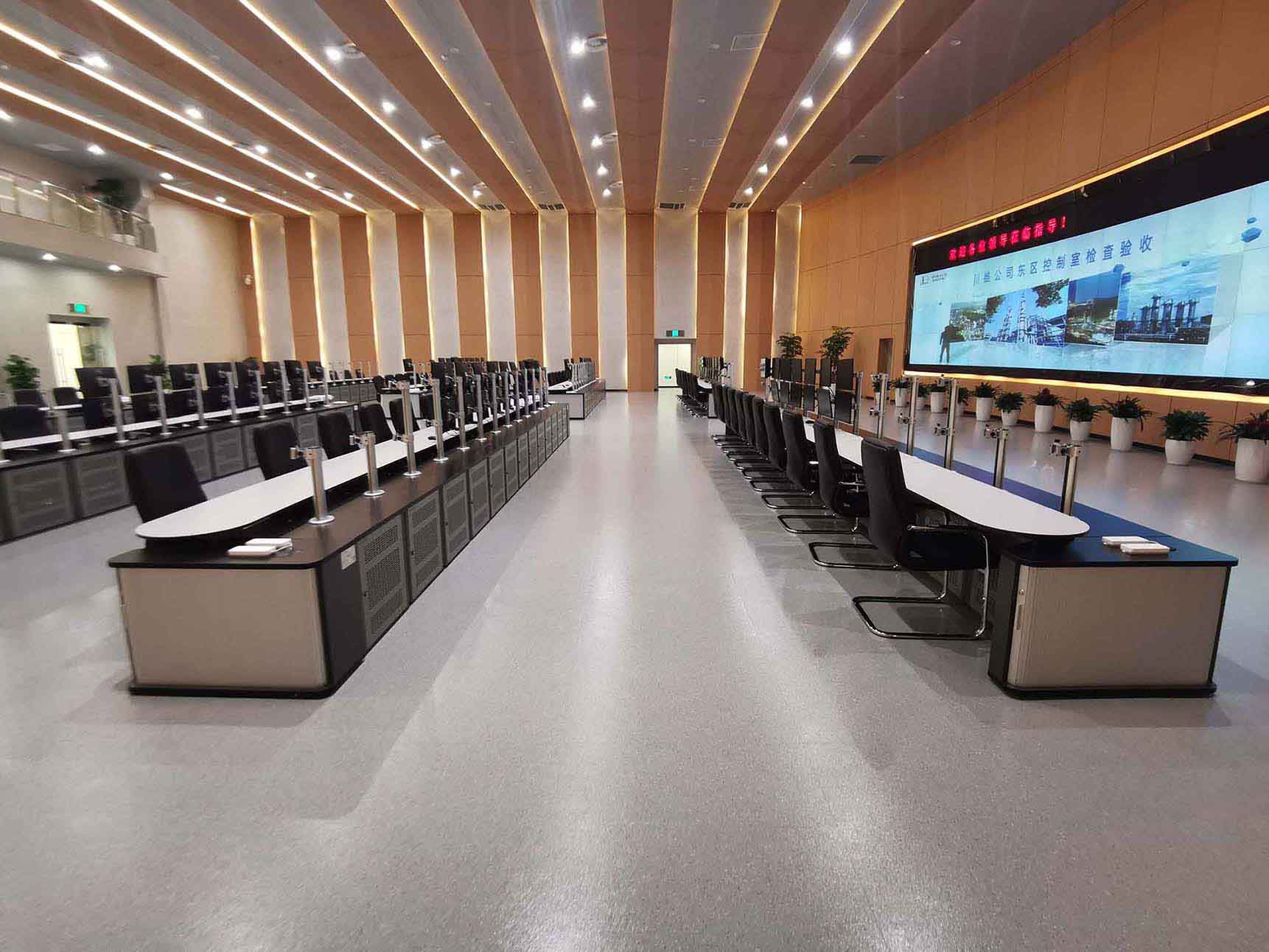

Copy and paste of the east and west control rooms

Sinopec Chongqing SVW Chemical Co.,Ltd. (hereinafter referred to as SVW) is located in Changshou District, Chongqing, and is the only natural gas chemical enterprise under Sinopec. SVW formerly known as Sichuan Vinylon Factory, was one of the earliest four chemical fiber bases in China established in the 1970s with the approval of the early national leaders Chairman Mao and Premier Zhou. Now it has developed into the largest natural gas fine chemical and new material enterprise in China, and a leading enterprise in the Chinese natural gas chemical industry.

In the second half of 2020, SVW was looking for a flooring suitable for industrial sites in their east control room's renovation, which required both wear and dirt resistance. After searching and comparing, the company leaders found the nora rubber flooring in the T3 terminal of Chongqing Jiangbei Airport. They then contacted us and invited us to participate in the renovation of the east control room. After communications and negotiations, Shanghai Chuangnuo participated in the project as a subcontractor and selected nora main product of 3.5mm tiles—norament® 926 grano and norament® 926 grano steptraeds as the flooring for the control room and public areas. After four months of intense preparation and construction, the completed nora flooring Looks satisfactory and passed the acceptance on March 8, 2021. Afterwards, every year we went for follow-up visits, the flooring showed a satisfactory effect and looked brand new after several years of use.

In the second half of 2020, SVW was looking for a flooring suitable for industrial sites in their east control room's renovation, which required both wear and dirt resistance. After searching and comparing, the company leaders found the nora rubber flooring in the T3 terminal of Chongqing Jiangbei Airport. They then contacted us and invited us to participate in the renovation of the east control room. After communications and negotiations, Shanghai Chuangnuo participated in the project as a subcontractor and selected nora main product of 3.5mm tiles—norament® 926 grano and norament® 926 grano steptraeds as the flooring for the control room and public areas. After four months of intense preparation and construction, the completed nora flooring Looks satisfactory and passed the acceptance on March 8, 2021. Afterwards, every year we went for follow-up visits, the flooring showed a satisfactory effect and looked brand new after several years of use.

SVW east control room

SVW east control room SVW has two factory, East and West, and two control rooms. The success of the flooring in the East impacted on the West. The west control room used linen flooring previously. After ten years, the dirt on the floor can not be cleaned, and the floor has raised and cracked in many places because of the moisture in the subfloor, which had a negative impact on daily use and corporate image. At the end of 2021, the company's leadership and user departments discussed and decided to install nora rubber flooring in the west control room refering to the East. So around 2022 New Year's Day, Shanghai Chuangnuo once again entered SVW. The renovation time is tight, only one month from decision, negotiation to arrival. Unlike the east, the west is a running control room. We can only use the overhaul holiday, a short ten days at the end of the year, to complete the subfloor treatment and self-leveling construction, and then complete the flooring installation when the staff come back working in the room. This time, we imported the flooring by air, in just over ten days, the flooring was transported from the German factory to SVW site. During the epidemic period, the floor went through multiple procedures such as disinfection and static testing before entering the factory site. Workers entered the site in late December to remove the original linen floor, sand and clean the floor, patch cracks, apply moisture-proof layers, and do a new self-leveling. These tasks were completed as scheduled before the end of the holiday. Then we started to install rubber flooring in sections of the control room. Before installing, some staff worried about the smell of the adhesive, but due to the excellent environmental performance of the German Uzin® products we used, no one metioned the smell again during the entire process, and the flooring was successfully installed in the contral room.

SVW west control room

SVW west control room There is one difference between two control rooms, that is the flooring in the west contral room is not waxed, because nora rubber flooring can be completely wax-free. This is more economical and environmentally friendly. The cleaner usually uses a walk-behind scrubber drier combined with water and 3M red buffer to walk around the ground every few days to keep the floor clean. It has been almost three years since the flooring installed, and we have never received any complaints from SVW. When we went for a follow-up visit, some old staff told us, 'It's totally different from the former flooring'. (Aug 5, 2024)